The whole production line of fully automatic disposable foam tableware equipment includes 4 sets

1. PS foam sheet extrusion line

Fully automatic vacuum forming machine

Crusher

Recycling granulator

Product Description:

1. Feeding part: feeding method, pneumatic feeding, double feeding shaft alternate feeding, simple and safe operation. The length of the discharge is controlled by a photoelectric switch.

2. Heating part: The heating box is all packed with asbestos wool and ceramic radiant tiles. The heating box can be moved back and forth for easy maintenance. The temperature is controlled by an intelligent temperature control meter, and the heating area reaches 1100×2400mm

3. Forming part: The forming method adopts the most recent comprehensive forming of vacuum, air pressure and molding. The vacuum pump is imported from Germany, with a volume of 50L; the upper and lower molds of the hydraulic station are independently controlled; the stroke control of the molding table is controlled by a photoelectric switch; the production efficiency reaches 3-8 seconds per mold. Maximum forming area: 1000×1100(mm)

4. Blanking part: hydraulic automatic control, the maximum pressure reaches 35 tons. The worktable is controlled by a photoelectric switch. Blanking area: 1000X1100(mm)

5. Stacking collection system: The stacking part is automatically controlled by PLC, the stacking quantity is set arbitrarily, and the stacking is automatic. The collecting part is conveyed by double conveyor belts, pneumatically controlled.

6. Waste rewinding: control mode is controlled by photoelectric switch

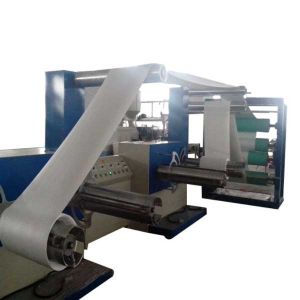

Fully automatic vacuum forming machine

The automatic vacuum forming machine is one of the machine which making the PS forming food box, it is a new type of thermoforming unit that integrates heating, forming and cutting, and manipulator grabbing. It can process almost all thermoforming plastic sheets. Automatic control, touch screen controls various action programs, easy operation, material saving and high production efficiency. It has the characteristics of reliable stability, large forming area, convenient cutting and easy operation, fast forming speed, high degree of automation and labor saving.

Fully automatic vacuum forming machine specification:

|

Parameter |

Unit |

Model |

|

|

HTC-1100 |

HTC-1250 |

||

|

Forming area |

Mm |

1100*1100 |

1100*1250 |

|

Cutting height |

mm |

160 |

160 |

|

Production efficiency |

Die/s |

3-6 3-4 |

3-6 |

|

Installation dimension |

m |

19*6*3 |

21*6*3 |

|

Installation power |

kw |

160 |

180 |

|

Powder supply |

3phase 380V 50HZ |

3phase 380V 50HZ |

|

can not be empty

The E-mail format is not correct

can not be empty

can not be empty