Masterbatch definition:

Masterbatch or plastic masterbatch is concentrated plastic particles composed of carrier resin, plastic fillers, plastic colorants and other additives. The term "masterbatch" refers to the master mix.

The application of masterbatch in plastic manufacturing has three main purposes:

- Reduce the amount of resin required

- Coloring of plastic products

- Enhance the functional properties of plastic products

Based on these functions, masterbatch is divided into three categories: color masterbatch, additive masterbatch and filler masterbatch.

Masterbatch manufacturing process

Generally speaking, the production of masterbatch includes the following 3 steps.

Step 1: Create a custom formula

The masterbatch manufacturer will identify and weigh resins, pigments, additive ratios, etc. The formulation depends on the type of masterbatch they want to produce.

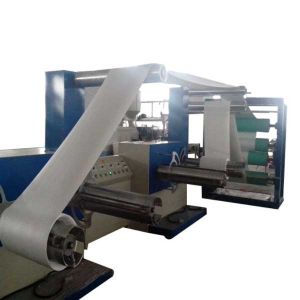

Step 2: Mix and Heat

After that, all the materials will be mixed together by heating and melting. The equipment for this process is usually twin-screw extrusion.

Step 3: Cool and Shape

The material in molten liquid form will be cooled and cut into small pellets.

Dust free products with a complete filtration up to 100µm, no skin sensitization, health guard of operators. Effective guarantee of activity of TMDM due to pre-dispersed masterbatch. Tack free products at room temperature, convenience and accuracy on ingredients. Lower Mooney viscosity at lower temperature (50ºC), higher quality of dispersion. Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thanks to filtration. Wider compatibility with other elastomers.

Application: Can be used as a single accelerator, as a secondary accelerator or as a sulphur donor in most sulphur-cured elastomers. Scorchy and gives fast cure rates. Produces an excellent vulcanisation plateau with good heat aging and compression set resistance in sulphurless and EV cure systems Good color retention is obtained in non-black vulcanisation. A valuable secondary accelerator for EPDM. May be used as a retarder in the vulcanisation of polychloroprene rubber with Willing ETU and also be used as bactericide and pesticide.

can not be empty

The E-mail format is not correct

can not be empty

can not be empty

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp